Harley-Davidson Rear Wheel Assembly Diagram: A Comprehensive Guide

This guide meticulously details Harley-Davidson rear wheel assembly, offering a comprehensive resource for both novice and experienced mechanics.

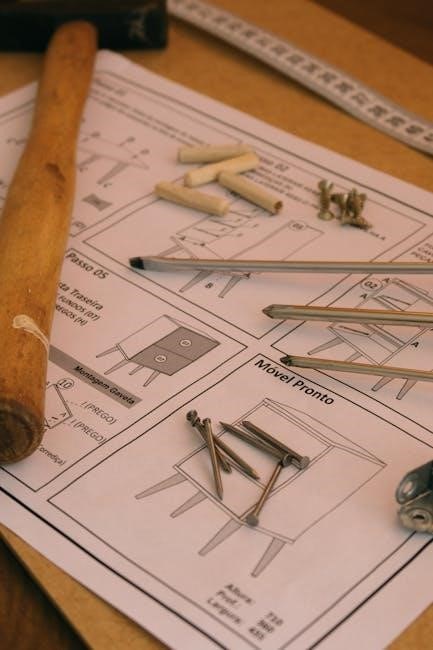

It incorporates exploded diagrams, parts lists (like the 2009-2011 F model), and installation procedures for optimal performance.

Harley-Davidson rear wheel assembly is a critical maintenance procedure, demanding precision and adherence to factory specifications. This process ensures safe operation and optimal handling characteristics of your motorcycle. Understanding the intricacies of wheel construction – hubs, spokes, bearings, and seals – is paramount.

This guide provides a detailed walkthrough, referencing model-specific diagrams (such as those for the Electra Glide Classic and 2009-2011 F models) and parts lists; Proper installation, utilizing approved wheels and kits, is crucial. Ignoring torque specifications or using incorrect parts can lead to wheel failure, posing significant safety risks.

We will cover everything from component identification to troubleshooting common issues like wheel wobble, offering a complete resource for successful rear wheel assembly.

Tools Required for Rear Wheel Assembly

Successful Harley-Davidson rear wheel assembly necessitates a specific toolkit. Essential items include a torque wrench, capable of accurately measuring values specified in the service manual (model-specific axle nut torque is vital). Socket sets, wrenches (metric and standard), and screwdrivers are also fundamental.

Specialized tools, such as a spoke wrench for tensioning, bearing press, and seal driver, are highly recommended. A wheel balancing stand ensures proper balance post-assembly, preventing vibrations. Access to a service manual, containing detailed diagrams and procedures, is indispensable.

Safety equipment – gloves and eye protection – are non-negotiable. Having a clean workspace and organized parts layout streamlines the process, minimizing errors during installation.

Harley-Davidson Rear Wheel Components Identification

Understanding componentry is crucial before beginning. The rear wheel assembly comprises several key elements. The hub, central to the wheel, dictates compatibility and bearing size. Spokes, connecting the hub to the rim, require correct tension for stability. Nipples adjust spoke tension, impacting wheel balance.

Bearings and seals ensure smooth rotation and prevent contamination. Spacers maintain proper alignment within the wheel and on the motorcycle. The axle secures the wheel, demanding precise torque specifications. Identifying these parts, referencing diagrams, and verifying fitment is paramount before installation.

Correct identification prevents errors and ensures a safe, functional wheel assembly.

Rear Wheel Hubs – Types and Specifications

Harley-Davidson rear wheel hubs vary significantly by model and year. Common types include cast aluminum, billet aluminum, and steel hubs, each offering different strength and weight characteristics. Specifications, like bolt patterns, bearing sizes, and hub width, are critical for compatibility.

The 2009-2011 F model hubs, for example, possess unique dimensions compared to Electra Glide Classic hubs. Proper identification requires referencing the parts manual and verifying specifications against the chosen wheel. Incorrect hub selection leads to installation issues and potential safety hazards.

Always confirm hub specifications before proceeding with assembly.

Spokes and Nipples – Materials and Torque

Harley-Davidson spoked wheels traditionally utilize stainless steel spokes and nipples, offering corrosion resistance and durability. However, materials can vary depending on the wheel’s intended use and aesthetic preferences. Achieving correct spoke tension is paramount for wheel integrity and safe operation.

Nipple torque specifications are crucial; over-tightening can damage the rim or spokes, while under-tightening leads to loosening and potential wheel wobble. A spoke torque wrench is essential for accurate tightening. Consistent tensioning, following a specific lacing pattern, ensures proper wheel balance and prevents stress concentrations.

Regularly inspect spoke tension and nipples for signs of loosening.

Bearings, Seals, and Spacers – Critical Dimensions

Harley-Davidson rear wheel assembly relies on precise bearing, seal, and spacer dimensions for smooth operation and longevity. Incorrect sizing can lead to premature wear, noise, and even catastrophic failure. Bearings are typically tapered roller bearings, designed to handle radial and axial loads.

Seals prevent lubricant leakage and contamination ingress. Spacers maintain correct bearing preload and wheel alignment within the hub. Always refer to the Harley-Davidson service manual for specific dimensions and tolerances for your motorcycle model.

Carefully inspect all components for damage before installation.

Step-by-Step Rear Wheel Assembly Instructions

Begin by thoroughly cleaning the wheel hub and inspecting it for any damage or corrosion. Next, install the bearings and seals, ensuring they are properly seated and lubricated. Proceed with spoking the wheel, adhering to the correct lacing pattern specified for your Harley-Davidson model – crucial for balance.

Evenly tension the spokes, using a spoke wrench and following a star pattern. Double-check spoke tension to eliminate wobble. Finally, verify proper wheel alignment before proceeding with installation on the motorcycle. Refer to detailed diagrams for visual guidance throughout the process.

Preparing the Wheel Hub

Initial preparation involves a meticulous cleaning of the Harley-Davidson wheel hub, removing all traces of old grease, dirt, and corrosion. Thoroughly inspect the hub for any cracks, warping, or damage to the bearing surfaces. Pay close attention to the hub’s internal features, ensuring they are free of debris.

Verify the hub’s runout using a dial indicator to confirm it meets factory specifications. Address any imperfections before proceeding. Lightly lubricate the bearing bores with appropriate grease to facilitate smooth bearing installation. This foundational step is critical for a properly assembled wheel.

Installing Bearings and Seals

Carefully install the bearings into the prepared wheel hub, utilizing a bearing press or a suitable socket and drift to avoid damage. Ensure bearings are seated squarely and fully within their respective bores. Next, install the seals, again using a seal driver to prevent distortion or damage to the sealing lips.

Proper seal installation is vital for preventing grease leakage and contamination. Verify the seals are flush with the hub surface. Lightly lubricate the bearings and seals with specified grease. Confirm free rotation of the hub after installation, indicating correct bearing seating and seal functionality.

Spoking the Wheel – Lacing Patterns

Spoking a wheel requires precision; select the correct lacing pattern for your Harley-Davidson model – typically a 3-cross or 4-cross pattern. Begin by inserting spokes, alternating sides to maintain even tension. Ensure nipples are lightly threaded onto the spokes before installation.

Follow a consistent pattern, working around the wheel in small increments. Gradually tighten the nipples, maintaining symmetry and preventing warping; Regularly check for spoke alignment and adjust as needed. Proper lacing ensures wheel strength, trueness, and longevity. Incorrect patterns can lead to spoke failure and instability.

Torque Specifications for Rear Wheel Assembly

Precise torque is crucial for safe and reliable rear wheel assembly. Axle nut torque values vary significantly by Harley-Davidson model; consult your service manual for the correct specification. Improper torque can lead to wheel detachment or bearing damage.

Spoke tensioning requires a spoke wrench and consistent tightening pattern. Achieve proper balance by measuring spoke tension with a tension meter, ensuring all spokes are within the manufacturer’s recommended range. Regularly re-check torque after initial miles ridden. Adhering to these specifications guarantees optimal wheel performance and rider safety.

Axle Nut Torque Values (Model Specific)

Determining the correct axle nut torque is paramount for Harley-Davidson rear wheel safety. Values differ substantially between models and years. For example, a 2009-2011 F model may require a different torque than an Electra Glide Classic. Always refer to the official Harley-Davidson service manual specific to your motorcycle’s year and model.

Ignoring these specifications can result in wheel instability, bearing failure, or even complete wheel detachment during operation. Using a calibrated torque wrench is essential. Double-check the torque value after the initial tightening and again after a short test ride.

Spoke Tensioning – Achieving Proper Balance

Proper spoke tension is critical for wheel trueness, strength, and longevity. Uneven tension leads to wheel wobble, spoke breakage, and potential failure. Achieving balance requires a systematic approach, tightening spokes incrementally and evenly around the wheel. A spoke wrench is essential for this process.

Utilize a tension meter for accurate readings, aiming for consistent tension across all spokes. Regularly check tension, especially after initial assembly and after riding; Addressing spoke breakage promptly prevents further damage and maintains wheel integrity. Remember, a properly tensioned wheel enhances handling and safety.

Rear Wheel Installation on Harley-Davidson Motorcycle

Installing the rear wheel demands precision and adherence to torque specifications. Begin by carefully aligning the wheel with the axle and swingarm, ensuring proper seating. Next, install the axle and appropriate spacers, referencing the Harley-Davidson service manual for your specific model.

Double-check spacer placement before tightening the axle nut to the manufacturer’s recommended torque value. Incorrect torque can lead to wheel instability or damage. Verify wheel alignment after installation, and always use approved wheels and installation kits to guarantee compatibility and safety.

Aligning the Rear Wheel

Precise wheel alignment is crucial for safe and optimal motorcycle handling. Begin by visually inspecting the wheel’s position relative to the swingarm, ensuring equal spacing on both sides. Utilize alignment tools, such as a laser alignment system or straightedge, to verify true alignment with the motorcycle’s frame.

Any misalignment can cause tire wear, handling instability, and potential safety hazards. Carefully adjust the axle position and swingarm alignment as needed, referencing the Harley-Davidson service manual for specific procedures. Re-check alignment after tightening the axle nut to ensure accuracy.

Installing the Axle and Spacers

Proper axle and spacer installation is vital for secure wheel mounting. Begin by applying a light coating of grease to the axle and spacer surfaces to prevent corrosion and facilitate smooth installation. Carefully insert the spacers into the wheel hub, ensuring they are seated correctly according to the Harley-Davidson parts diagram.

Next, slide the axle through the wheel hub and swingarm, aligning it with the axle holes. Install the axle nut and tighten it to the manufacturer’s specified torque value – referencing model-specific torque specifications is essential. Double-check the axle nut’s tightness after initial ride.

Troubleshooting Common Rear Wheel Assembly Issues

Addressing rear wheel issues promptly ensures rider safety and optimal motorcycle performance. Wheel wobble and runout often stem from improperly tensioned spokes or a bent rim; careful spoke adjustment and wheel truing are crucial. Spoke breakage can result from impacts or insufficient tension – preventative maintenance, including regular spoke checks, is key.

If encountering wobble, inspect bearings for wear and ensure proper axle nut torque. For broken spokes, replace them immediately with the correct specification. Always verify wheel alignment after any repair or assembly. Consulting a Harley-Davidson service manual is recommended.

Wheel Wobble and Runout – Causes and Solutions

Wheel wobble and runout significantly impact ride quality and safety, demanding immediate attention. Common causes include loose or unevenly tensioned spokes, bent rims, worn wheel bearings, and improper axle nut torque. Runout refers to side-to-side deviation, while wobble indicates vertical movement.

Solutions involve systematically checking and adjusting spoke tension, ensuring even distribution. Inspect the rim for bends or damage, and replace if necessary. Replace worn bearings and verify correct axle nut torque specifications. Proper wheel alignment is paramount; utilize truing stands for accurate adjustments.

Spoke Breakage – Prevention and Repair

Spoke breakage is a frequent issue, often stemming from impact damage, improper tension, or corrosion. Prevention centers around regular spoke tension checks and maintenance, especially after hitting potholes or rough terrain. Consistent tension distributes stress evenly, minimizing the risk of failure.

Repair typically involves replacing the broken spoke with a new one of the correct length and material. Detension surrounding spokes, remove the damaged component, install the replacement, and retension the entire wheel. Professional assistance is recommended if you lack experience, ensuring proper lacing patterns and torque are maintained for structural integrity.

Harley-Davidson Rear Wheel Parts Diagrams (Model Specific)

Detailed parts diagrams are crucial for successful rear wheel assembly and repair. These visual guides illustrate the precise arrangement of each component, facilitating accurate identification and replacement. Accessing model-specific diagrams, such as those for the 2009-2011 F model, is paramount.

Similarly, diagrams for the Electra Glide Classic showcase unique component layouts. These resources, often found in Harley-Davidson service manuals or online parts finders, depict hubs, spokes, nipples, bearings, seals, and spacers. Utilizing these diagrams ensures correct part selection and proper assembly, preventing compatibility issues and ensuring optimal wheel performance.

2009-2011 F Model Rear Wheel Diagram

The 2009-2011 Harley-Davidson F model rear wheel diagram is an essential resource for disassembly, assembly, and parts identification. This exploded view meticulously details each component, including the hub, spokes, nipples, bearings, seals, and axle spacers. It’s vital for understanding the wheel’s construction.

Accessing this diagram, often found within the official Harley-Davidson parts manual, allows for accurate parts ordering and correct installation procedures. Proper referencing of this diagram prevents errors during reassembly, ensuring wheel integrity and safe operation. It’s a cornerstone for any maintenance or repair work performed on this specific model.

Electra Glide Classic Rear Wheel Diagram

The Electra Glide Classic rear wheel diagram provides a detailed visual breakdown of this model’s wheel assembly. This comprehensive illustration showcases the precise arrangement of components – from the wheel hub and spokes to the critical bearings, seals, and axle components. It’s a crucial tool for maintenance and repair.

Utilizing this diagram, sourced from Harley-Davidson parts manuals, ensures accurate parts identification and correct installation sequences. Proper understanding of this diagram minimizes errors during reassembly, guaranteeing optimal wheel performance and rider safety. Referencing it is paramount when sourcing replacement parts or undertaking any wheel-related service.

Approved Wheels and Installation Kits

Harley-Davidson strongly advises utilizing only wheels and installation kits specifically approved for your motorcycle model. Deviating from this recommendation can compromise structural integrity and safety. Compatibility is paramount; ensure the chosen components are designed to work harmoniously with your bike’s specifications.

Contacting an authorized Harley-Davidson dealer is the best practice to verify fitment and ensure you receive genuine, tested parts. These kits often include all necessary hardware, spacers, and bearings, streamlining the installation process. Using non-approved components may void warranties and potentially lead to hazardous riding conditions. Prioritize safety and adherence to manufacturer guidelines.

Finding Harley-Davidson Rear Wheel Parts

Locating genuine Harley-Davidson rear wheel parts is crucial for maintaining your motorcycle’s performance and safety. Ronnies Harley-Davidsons offers a comprehensive Street Bike Parts Finder, simplifying the search process. Online Harley-Davidson parts finders, accessible through the official website or authorized dealers, allow you to identify components using your bike’s model and year.

Authorized dealerships provide expert assistance and ensure you receive authentic parts. When sourcing parts, always verify compatibility with your specific model. Consider exploring online marketplaces, but prioritize reputable sellers to avoid counterfeit or substandard components. Maintaining a reliable source for parts is essential for successful repairs and upkeep.

Safety Precautions During Rear Wheel Assembly

Prioritize safety throughout the rear wheel assembly process. Always disconnect the battery to prevent accidental electrical shorts. Wear appropriate safety glasses and gloves to protect your eyes and hands from debris and sharp edges. Ensure the motorcycle is securely supported on a lift or stand to prevent tipping.

Use properly calibrated torque wrenches to tighten fasteners to the specified values, avoiding over or under-tightening. Be mindful of heavy components and utilize appropriate lifting techniques. Inspect all parts for damage before installation. If unsure about any step, consult a Harley-Davidson service manual or a qualified mechanic.

Resources for Harley-Davidson Rear Wheel Information

Accessing reliable information is crucial for successful rear wheel assembly. Harley-Davidson service manuals provide detailed diagrams, torque specifications, and step-by-step instructions specific to your model. Online Harley-Davidson parts finders, like Ronnie’s, assist in identifying correct components and exploded views.

SRF Audio and Podcasts offer a wealth of Swiss information, though not directly related to motorcycle repair. Remember to verify compatibility when using aftermarket parts. Consulting experienced mechanics or online forums dedicated to Harley-Davidson can also provide valuable insights and troubleshooting advice. Prioritize official documentation for accuracy.

Harley-Davidson Service Manuals

Genuine Harley-Davidson service manuals are indispensable resources for rear wheel assembly. They contain detailed, model-specific exploded diagrams illustrating every component and its precise location. These manuals provide accurate torque specifications, crucial for safe and reliable wheel installation, preventing issues like wobble or spoke breakage.

Step-by-step instructions guide mechanics through each stage, from hub preparation to final axle nut tightening. Manuals also outline proper bearing installation and spoke tensioning techniques. Utilizing the correct manual ensures adherence to Harley-Davidson’s engineering standards, maximizing performance and safety. They are the foundation for a successful assembly.

Online Harley-Davidson Parts Finders

Utilizing online Harley-Davidson parts finders streamlines the rear wheel assembly process. These digital catalogs provide interactive exploded diagrams, allowing users to identify specific components by model and year. They are invaluable for locating correct parts, ensuring compatibility and avoiding costly errors during reassembly.

These finders often link directly to authorized dealers, facilitating easy parts procurement. They complement service manuals by visually representing component relationships. Accessing these resources ensures accurate parts identification, crucial for a successful wheel installation. Ronnie’s Harley-Davidson is a notable example, offering a comprehensive parts finder for various models.