LAPD Manual: A Comprehensive Overview (Updated 12/22/2025)

This manual details current LAPD standards, policies, practices, and operating procedures, alongside training materials, as of today’s date, December 22, 2025.

The Los Angeles Police Department (LAPD) Manual serves as the foundational document governing all departmental operations, ensuring consistency and accountability across the force. Updated as of December 22, 2025, this comprehensive guide consolidates current standards, policies, practices, and detailed operating procedures. It’s a critical resource for all sworn and civilian personnel, outlining expectations and providing a framework for effective law enforcement.

This manual isn’t static; it undergoes quarterly revisions to reflect evolving legal landscapes, legislative updates – such as Senate Bills 1421/SB 16 and 989, and Assembly Bill 2907 – and best practices in policing. The manual extends to cover specific units like the LAPD SWAT team and also acknowledges the relationship with the Los Angeles County Sheriff’s Department (LASD). It’s designed to promote transparency and guide officers in navigating complex situations, ultimately enhancing public safety and trust within the community.

II. Historical Context of LAPD Policies

The evolution of LAPD policies reflects a dynamic interplay between societal expectations, legal precedents, and internal departmental reforms. Early policing strategies, while focused on order maintenance, gradually incorporated principles of community policing and procedural justice. Landmark legal cases and civil rights movements significantly shaped the department’s approach to use of force, arrest procedures, and citizen interactions.

Over decades, the LAPD has responded to legislative changes – notably, recent Senate Bills (SB 1421/SB 16, SB 989) and Assembly Bill 2907 – increasing transparency regarding officer conduct. The manual’s current iteration builds upon this history, aiming to balance effective crime prevention with constitutional safeguards. Understanding this historical context is crucial for interpreting current policies and appreciating the ongoing commitment to professionalization and accountability within the department. The manual’s revisions demonstrate a continuous effort to adapt to a changing world.

III. General Provisions — Volume 0

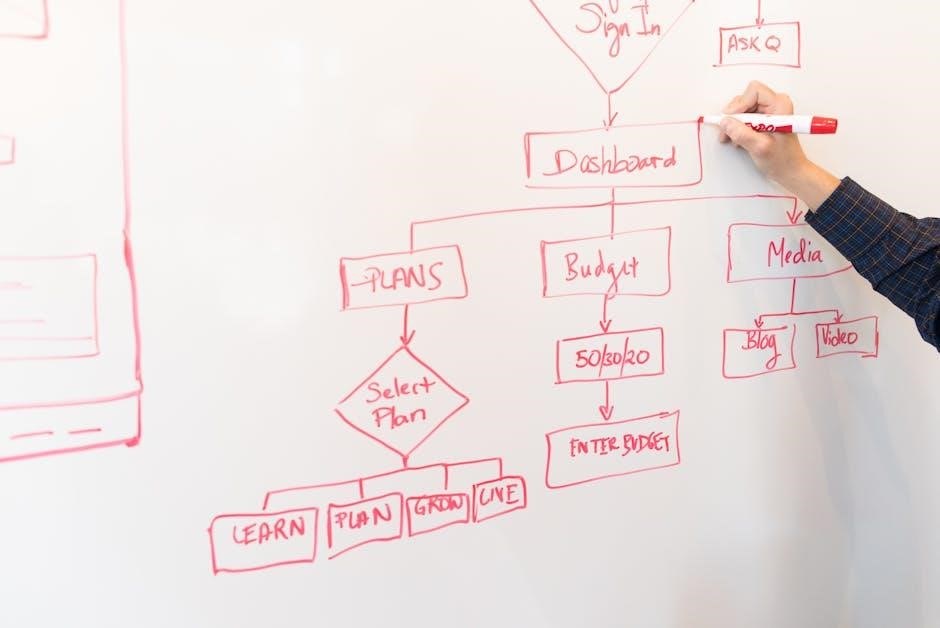

Volume 0 of the LAPD Manual establishes foundational principles governing all departmental operations. This section encompasses the Code of Ethics, outlining expected standards of conduct for all personnel, and the Preamble to the Manual, articulating the department’s core values and mission. A critical component is the process for Quarterly Updates and Revisions, ensuring the manual remains current with evolving legal landscapes and best practices.

These general provisions serve as the bedrock for all subsequent policies and procedures detailed in Volumes 1 and 2. They emphasize integrity, professionalism, and a commitment to serving the community with fairness and respect. Adherence to these foundational principles is mandatory for all LAPD personnel, fostering a culture of accountability and ethical decision-making. Regular review and updates are vital to maintaining the manual’s relevance and effectiveness.

III.A. Code of Ethics

The LAPD Code of Ethics demands unwavering integrity from every officer, emphasizing honesty, truthfulness, and adherence to the law. Officers are expected to demonstrate impartiality, avoiding bias and prejudice in all interactions. Maintaining confidentiality is paramount, protecting sensitive information and respecting individual privacy rights.

This code stresses the responsible use of authority, prohibiting abuse of power or excessive force. Officers must uphold public trust through transparency and accountability, actively addressing misconduct and fostering positive community relations. Professional conduct, both on and off duty, is essential, reflecting positively on the department’s reputation. The Code of Ethics isn’t merely a set of rules, but a commitment to ethical policing and public service, guiding decision-making in complex situations.

III.B. Preamble to the Manual

This LAPD Manual serves as the definitive guide for all personnel, outlining the department’s policies and procedures; It’s designed to ensure consistent, lawful, and ethical policing practices throughout the City of Los Angeles. The manual reflects the LAPD’s commitment to constitutional policing, respecting the rights of all individuals while diligently fulfilling its duty to protect and serve.

Regular updates, as indicated by the current date of December 22, 2025, are crucial to adapt to evolving legal landscapes and best practices. This document aims to provide clarity and direction, fostering professionalism and accountability within the department. Adherence to these guidelines is mandatory, promoting public trust and reinforcing the LAPD’s dedication to maintaining order and justice within the community.

III.C. Quarterly Updates and Revisions

The LAPD Manual undergoes rigorous quarterly reviews and revisions to maintain alignment with evolving legal mandates, departmental best practices, and emerging community needs. Updates incorporate changes stemming from legislative actions, such as Senate Bills 1421/SB 16 and more recent directives like Senate Bill 989 (March 18, 2025) and Assembly Bill 2907 (January 9, 2025).

These revisions ensure all personnel operate under the most current guidelines regarding policies and procedures. The process involves input from various stakeholders, including legal counsel, training divisions, and field personnel. All updates are documented, and personnel are responsible for staying informed. This commitment to continuous improvement reinforces the LAPD’s dedication to transparency, accountability, and effective policing strategies.

IV. Core Policy Volume ー Volume 1

Volume 1 of the LAPD Manual constitutes the core of departmental policy, outlining fundamental guidelines for officer conduct and operational procedures. Key areas covered include the Use of Force Continuum, detailing escalating response levels to ensure proportionality and de-escalation techniques are prioritized. Comprehensive protocols for Arrest Procedures and Rights of the Accused are also detailed, emphasizing adherence to constitutional safeguards and due process.

Furthermore, this volume addresses Vehicle Pursuit Policies, balancing the need for apprehension with public safety considerations. These policies are regularly updated to reflect legal changes and best practices, ensuring officers are equipped with the knowledge to navigate complex situations effectively and responsibly.

IV.A. Use of Force Continuum

The LAPD’s Use of Force Continuum is a critical component of departmental policy, guiding officers in applying appropriate force levels based on the totality of circumstances. This continuum progresses through stages, beginning with officer presence, verbal commands, and the deployment of less-lethal options like pepper spray or tasers. Deadly force is reserved as a last resort, authorized only when an officer reasonably believes their life or the life of another is in imminent danger.

Training emphasizes de-escalation techniques at each stage, prioritizing conflict resolution and minimizing the need for force. All uses of force are subject to rigorous review and documentation, ensuring accountability and adherence to constitutional standards. The continuum is regularly updated to reflect legal precedents and evolving best practices;

IV.B. Arrest Procedures and Rights of the Accused

LAPD arrest procedures are meticulously defined to ensure compliance with the Fourth, Fifth, and Sixth Amendments of the U.S. Constitution. Officers must establish probable cause before making an arrest, clearly informing the accused of their Miranda rights – the right to remain silent and the right to an attorney – prior to interrogation.

Search and seizure protocols adhere to strict legal standards, requiring warrants based on probable cause unless exceptions apply. Detailed documentation of all arrest-related activities, including the justification for the arrest and any evidence collected, is mandatory. The LAPD emphasizes respectful treatment of all individuals, regardless of their legal status, throughout the arrest process, upholding due process and protecting civil liberties.

IV.C. Vehicle Pursuit Policies

The LAPD’s vehicle pursuit policy prioritizes public safety while balancing the need to apprehend fleeing suspects. Pursuits are authorized only when the risk posed by the suspect’s escape outweighs the danger created by the pursuit itself. Factors considered include the severity of the suspected crime, the suspect’s demonstrated threat to public safety, and environmental conditions.

Strict guidelines govern pursuit tactics, including speed limits, the use of vehicle maneuvers, and the involvement of air support. Officers are required to continuously assess the risks during a pursuit and terminate it if the danger becomes too great. Comprehensive reporting and review of all pursuits are conducted to identify areas for improvement and ensure adherence to policy, minimizing potential harm to officers and civilians.

V. Organizational Structure ー Volume 2

Volume 2 of the LAPD Manual details the department’s hierarchical structure, outlining the clear chain of command from the Chief of Police down to patrol officers. It defines the functions and responsibilities of various divisions, including Patrol, Detectives, and specialized units like SWAT. This section clarifies reporting lines and ensures accountability throughout the organization.

Furthermore, it addresses the relationship between the LAPD and the Los Angeles County Sheriff’s Department (LASD), recognizing the LASD’s broader jurisdictional reach. The manual delineates areas of concurrent jurisdiction and protocols for interagency cooperation, emphasizing coordinated responses to county-wide incidents. Understanding this structure is crucial for effective communication and operational efficiency within the department and with external agencies.

V.A. Chain of Command within the LAPD

The LAPD’s chain of command is a strictly hierarchical structure, beginning with the Chief of Police and cascading through a series of ranks including Commanders, Captains, and Lieutenants. This clearly defined structure ensures accountability and facilitates efficient decision-making. Each rank possesses specific responsibilities and authority levels, detailed within this manual.

Patrol officers report to Sergeants, who in turn report to Lieutenants overseeing specific divisions or areas. Captains manage larger commands, while Commanders oversee multiple divisions or specialized units. The manual emphasizes the importance of respecting this chain of command and adhering to established reporting protocols; Deviation from this structure requires explicit authorization and documentation, ensuring operational control and clear lines of responsibility throughout the department.

V.B. Functions of Specialized Units (SWAT, Detectives)

The LAPD utilizes specialized units to address complex and high-risk situations. The SWAT team, a highly trained tactical unit, responds to barricaded suspects, hostage situations, and high-risk warrant services, employing specialized equipment and techniques. Detectives, organized into various divisions (e.g., homicide, robbery, assault), investigate criminal activity, gather evidence, and prepare cases for prosecution.

This manual details the specific protocols for inter-unit cooperation and information sharing. Specialized units operate under strict guidelines, ensuring adherence to legal standards and departmental policies. The functions of the Los Angeles County Sheriff’s Department (LASD) are distinct, covering a larger geographical area, but collaboration occurs on joint operations as outlined in interagency agreements. Proper coordination and communication between these units are paramount for effective law enforcement.

V.C. Relationship with Los Angeles County Sheriff’s Department (LASD)

The Los Angeles Police Department (LAPD) and the Los Angeles County Sheriff’s Department (LASD) maintain a complex relationship defined by jurisdictional boundaries and collaborative agreements. The LASD’s jurisdiction encompasses unincorporated areas of Los Angeles County, which are larger than the city limits policed by the LAPD. While distinct entities, both agencies frequently engage in joint operations, particularly concerning regional crime trends and large-scale emergencies.

This manual outlines the protocols for interagency communication, resource sharing, and coordinated responses. Clear delineation of responsibilities is crucial to avoid jurisdictional disputes. Mutual aid agreements facilitate assistance during critical incidents. Understanding the differing structures – the LAPD as a police department versus the LASD as a sheriff’s office – is vital for effective collaboration, ensuring seamless law enforcement services across Los Angeles County.

VI. Legal and Legislative Updates

This section details recent legal and legislative changes impacting LAPD policies and procedures. Critical updates include Senate Bill 1421/SB 16, mandating the disclosure of peace officer records related to use of force, dishonesty, and sexual misconduct. Further, Chief of Detectives Notices regarding Senate Bill 989 (March 18, 2025) and Assembly Bill 2907 (January 9, 2025) are incorporated, outlining specific implementation guidelines.

These legislative actions necessitate ongoing review and revision of departmental protocols to ensure compliance. The LAPD is committed to transparency and accountability, reflected in these updated policies. Officers are required to stay informed about these changes through mandatory training and regular briefings. This section serves as a central repository for all legally mandated adjustments to departmental operations, ensuring adherence to California law.

VI.A. Senate Bill 1421/SB 16 – Peace Officer Disclosures

Senate Bills 1421 and 16 significantly altered public access to peace officer records within the LAPD. Prior to these bills, records pertaining to police misconduct were largely confidential. SB 1421 mandated the release of records concerning use of force resulting in serious bodily injury or death, sustained findings of dishonesty, and confirmed instances of sexual misconduct.

SB 16 further expanded disclosure requirements, impacting investigations of officer misconduct. The LAPD has implemented procedures to comply with these laws, balancing transparency with officer privacy rights. This includes a review process to redact information protected by law. These disclosures aim to enhance public trust and accountability within the department, fostering a more open relationship between the LAPD and the communities it serves.

VI.B. Senate Bill 989 – Chief of Detectives Notice (March 18, 2025)

A Chief of Detectives Notice, dated March 18, 2025, addressed Senate Bill 989 and its implications for LAPD investigative procedures. This bill mandates specific notifications to chiefs of police regarding certain custodial interrogations; Specifically, it requires notification when a peace officer intends to interview an individual in custody who has invoked their Miranda rights.

The notice details the protocol for LAPD detectives, emphasizing the importance of documenting these notifications and ensuring compliance with SB 989’s requirements. This aims to safeguard the rights of individuals during custodial interrogations and maintain the integrity of the investigative process. Strict adherence to these guidelines is crucial to avoid potential legal challenges and uphold constitutional protections.

VI.C. Assembly Bill 2907 – Chief of Detectives Notice (January 9, 2025)

On January 9, 2025, a Chief of Detectives Notice was issued concerning Assembly Bill 2907, outlining new requirements for peace officer disclosures. This legislation expands upon Senate Bill 1421 and SB 16, further broadening the scope of records available to the public regarding police misconduct and use of force incidents.

The notice instructs all LAPD personnel to familiarize themselves with AB 2907’s provisions, particularly regarding the release of records pertaining to sustained findings of dishonesty related to critical incidents. It emphasizes the importance of accurate and thorough documentation to facilitate compliance with public records requests. The LAPD is committed to transparency and accountability, and this bill reinforces those principles, requiring diligent adherence to disclosure protocols.

VII. Policies and Procedures – Detailed Examination

This section provides a comprehensive review of core LAPD policies and procedures, intentionally designed to ensure consistent application across all divisions. Detailed examination covers critical areas, including evidence handling and maintaining a strict chain of custody to preserve the integrity of investigations. Internal Affairs investigations are also scrutinized, emphasizing fair and impartial processes for addressing misconduct allegations.

Furthermore, this section delves into Human Relations and Community Policing policies, highlighting the LAPD’s commitment to building trust and fostering positive relationships with the communities it serves. These procedures are regularly updated to reflect best practices and legal requirements, ensuring alignment with departmental goals and ethical standards.

VII.A. Evidence Handling and Chain of Custody

Maintaining a meticulous chain of custody is paramount within the LAPD, ensuring the admissibility of evidence in legal proceedings. All evidence collected must be properly documented, including date, time, location, and collecting officer’s information. Strict protocols govern the handling, storage, and transfer of evidence, minimizing the risk of contamination or loss.

Detailed records are required at each stage, documenting who possessed the evidence and for what purpose. When State funds are utilized for evidence purchase, comprehensive records of denominations and serial numbers are mandatory. Any deviation from established procedures necessitates a written explanation. This rigorous system upholds the integrity of investigations and demonstrates the LAPD’s commitment to due process.

VII.B. Internal Affairs Investigations

The LAPD’s Internal Affairs Group (IAG) is responsible for investigating allegations of misconduct against department personnel. These investigations are initiated based on complaints from the public, fellow officers, or identified through internal monitoring. All allegations are thoroughly examined, ranging from excessive force and dishonesty to violations of department policies and criminal activity.

IAG investigations adhere to strict guidelines, ensuring fairness and objectivity. Officers are entitled to due process, including the right to representation. Findings can result in disciplinary action, ranging from counseling to termination. Transparency and accountability are central to the IAG’s mission, fostering public trust and maintaining the highest ethical standards within the LAPD. Detailed records of all investigations are maintained.

VII.C. Human Relations and Community Policing Policies

The LAPD prioritizes building strong relationships with the diverse communities it serves. Community Policing policies emphasize proactive problem-solving, collaboration, and engagement with residents and local organizations. Officers are encouraged to participate in community events and build trust through positive interactions.

Human Relations policies focus on fostering a respectful and inclusive environment, both within the department and in interactions with the public. The LAPD’s Office of Human Relations provides training on cultural sensitivity, implicit bias, and de-escalation techniques. These initiatives aim to reduce disparities, promote fairness, and ensure equitable treatment for all. The department actively seeks feedback from community members to improve its policies and practices, fostering mutual understanding and cooperation.

VIII. Training Materials and Standards

Comprehensive training is fundamental to LAPD operations, encompassing legal updates, policy changes, and best practices. Initial recruit training covers law, defensive tactics, firearms, de-escalation techniques, and community policing principles. Ongoing professional development ensures officers remain current on evolving legal standards, including Senate Bill 1421/SB 16 regarding peace officer disclosures and updates from Senate Bill 989 and Assembly Bill 2907.

Specialized units, like SWAT and Detectives, receive advanced training specific to their roles. Training materials are regularly updated and aligned with departmental policies and procedures. The LAPD emphasizes scenario-based training to prepare officers for real-world challenges, focusing on critical decision-making and ethical conduct. All training adheres to state POST (Peace Officer Standards and Training) requirements.

IX. Los Angeles Port Police – Specific Policies

The Los Angeles Port Police (LAPP) operates under the umbrella of the LAPD, yet maintains specific policies tailored to the unique environment of the Port of Los Angeles. These policies address maritime security, cargo theft prevention, and international border enforcement. LAPP officers receive specialized training in areas like vessel boarding procedures, hazardous materials response, and federal maritime law.

All current standards, policies, practices, operating procedures, and educational materials applicable to the LAPP are included within this manual, mirroring LAPD’s core principles but adapted for port-specific challenges. This includes evidence handling protocols, chain of custody procedures, and adherence to both state and federal regulations. LAPP collaborates closely with the Department of Homeland Security and U.S. Customs and Border Protection.

X. Insurance Considerations for LAPD Operations

Insurance coverage for LAPD operations is a complex matter, significantly impacted by recent events and increasing liability concerns. Due to frequent incidents and associated legal claims, obtaining affordable insurance has become increasingly difficult, with some reports suggesting extremely high premiums. The Department actively manages risk mitigation strategies to control insurance costs, including enhanced training programs and revised use-of-force policies.

When state funds are utilized for evidence purchases, detailed records of denominations, serial numbers, series, and other identifying information must be meticulously maintained for insurance and auditing purposes. The LAPD’s Office of Risk Management continuously evaluates coverage options and collaborates with legal counsel to ensure adequate protection against potential liabilities. Future increases in insurance premiums across all US police departments are anticipated.