The Secretary of the Navy (SECNAV) administers the DON Correspondence Management Program‚ coordinating changes to this manual․ This document establishes standardized guidelines for all Navy communication․

Effective communication is vital for mission success‚ requiring clarity‚ accuracy‚ and adherence to established protocols within the Department of the Navy․

Purpose and Scope of the Manual

This manual provides a comprehensive framework for all official correspondence originating from or directed to Department of the Navy (DON) personnel․ Its primary purpose is to ensure uniformity‚ efficiency‚ and professionalism in all written communications․ The scope encompasses all forms of Navy correspondence‚ including official memorandums (MEMOs)‚ letters‚ and electronic mail (email)․

It applies to all active duty‚ reserve‚ and civilian employees of the DON․ Adherence to these guidelines promotes clarity‚ reduces ambiguity‚ and facilitates effective information exchange․ The manual aims to standardize formats‚ address proper tone‚ and establish best practices for handling and routing correspondence‚ ultimately supporting the Navy’s operational readiness and administrative effectiveness․

Authority and Responsibility (SECNAV)

The Secretary of the Navy (SECNAV) holds ultimate authority for the Department of the Navy (DON) Correspondence Management Program․ SECNAV is responsible for establishing policy and ensuring consistent application of these standards across the entire Navy enterprise․ This includes approving revisions to this manual and overseeing its implementation․

SECNAV delegates responsibility for day-to-day program administration to designated officials within the DON․ These individuals are tasked with coordinating proposed changes‚ providing guidance to personnel‚ and monitoring compliance․ Maintaining effective communication protocols is crucial for mission success‚ and SECNAV’s oversight ensures accountability and standardization․

Fundamental Principles of Navy Correspondence

Navy correspondence demands unwavering adherence to principles of clarity‚ accuracy‚ and a professional tone․ These guidelines ensure effective communication and maintain operational readiness․

Clarity and Conciseness

Achieving clarity and conciseness in Navy correspondence is paramount․ Every communication should convey its message directly and efficiently‚ avoiding ambiguity or unnecessary jargon․ Use simple‚ straightforward language‚ and structure sentences for easy understanding․ Eliminate redundant phrases and focus on essential information․

Concise writing respects the recipient’s time and ensures the message is readily absorbed․ Prioritize brevity without sacrificing accuracy or completeness․ Effective communication minimizes the potential for misinterpretation and promotes swift‚ informed decision-making throughout the Department of the Navy․ Remember‚ impactful messages are often the most succinct․

Accuracy and Completeness

Maintaining accuracy and completeness is non-negotiable in all Department of the Navy correspondence․ Information presented must be factually correct‚ verifiable‚ and free from errors․ Thoroughly review all data‚ dates‚ and names before dissemination․ Incomplete information can lead to flawed decisions and operational inefficiencies․

Ensure all relevant details are included to provide a comprehensive understanding of the subject matter․ Supporting documentation should be attached as necessary․ Prioritize meticulousness and double-check all aspects of the communication․ Accurate and complete correspondence fosters trust and reliability within the Navy’s operational framework․

Proper Tone and Style

Navy correspondence demands a professional‚ respectful‚ and objective tone․ Avoid colloquialisms‚ slang‚ or overly casual language․ Maintain a formal style appropriate for official communication‚ reflecting the seriousness and importance of the subject matter․ Use active voice whenever possible for clarity and directness․

Correspondence should be courteous and considerate‚ even when addressing sensitive or challenging issues․ Avoid accusatory or inflammatory language․ Strive for conciseness while ensuring all necessary information is conveyed․ Adhering to these stylistic guidelines enhances the credibility and effectiveness of all Department of the Navy communications․

Types of Navy Correspondence

The Department of the Navy utilizes various communication methods‚ including official MEMOs‚ formal Letters‚ and increasingly‚ Electronic Mail (Email) for efficient information exchange․

Official Memorandums (MEMOs)

MEMOs serve as the primary method for internal communication within the Department of the Navy․ They facilitate the conveyance of policy‚ procedures‚ and informational updates amongst personnel․ A properly formatted MEMO adheres to strict guidelines regarding subject lines‚ addressees‚ and content organization․

These documents should be concise and focused‚ directly addressing the intended audience and purpose․ Clarity is paramount; avoid jargon and ambiguous language․ MEMOs are generally used for matters not requiring the formality of a letter‚ offering a streamlined approach to internal correspondence․ Proper distribution and tracking are essential for accountability and efficient workflow․

Utilizing standardized templates ensures consistency and professionalism across all Navy activities․

Letters

Letters represent the formal mode of communication utilized by the Department of the Navy when addressing external entities or requiring a higher degree of official documentation․ They are employed for correspondence with other government agencies‚ private organizations‚ and individuals outside the Navy’s internal structure․

Navy letters demand meticulous attention to formatting‚ including proper addressing‚ salutations‚ and closing remarks․ Maintaining a professional tone and adhering to grammatical standards are crucial․ Letters often convey sensitive information or establish official records‚ necessitating accuracy and completeness․

Careful consideration must be given to the content‚ ensuring it reflects the Navy’s values and policies․

Electronic Mail (Email) Usage

Electronic mail (Email) serves as a rapid and efficient communication method within the Department of the Navy‚ though it requires careful adherence to established guidelines․ While convenient‚ email lacks the formality of official letters or memorandums and should be used judiciously․

Subject lines must be concise and informative‚ accurately reflecting the email’s content․ Maintaining a professional tone is paramount‚ even in informal exchanges․ Sensitive or classified information should never be transmitted via unencrypted email․

Email chains should be kept concise‚ and unnecessary recipients avoided to maintain efficiency and security․

Formatting and Structure of Correspondence

Standardized formatting ensures readability and professionalism in all Navy correspondence․ Consistent page layouts‚ margins‚ fonts‚ and spacing are crucial for clarity and efficient communication․

Standard Page Layout and Margins

Navy correspondence demands strict adherence to page layout standards for a professional appearance and ease of reading․ All documents must utilize 8․5 x 11-inch white paper․ Top margins should measure one inch‚ while bottom and side margins are set at one inch as well․

These margins facilitate binding and ensure sufficient white space for readability․ Headers and footers must remain within the designated margin areas․ Precise adherence to these specifications promotes uniformity across all official Navy communications‚ enhancing clarity and reflecting a commitment to professionalism․ Consistent formatting aids in efficient processing and archiving of vital information․

Font and Spacing Requirements

Navy correspondence mandates specific font and spacing guidelines to ensure readability and a professional presentation․ Times New Roman‚ 12-point font‚ is the standard․ Single-spacing within paragraphs is required‚ with a double space between paragraphs for clear demarcation․

All documents should be fully justified‚ aligning text evenly on both left and right margins․ These standards promote consistency and ease comprehension․ Deviations from these requirements are generally discouraged unless specifically authorized․ Adhering to these guidelines ensures all official Navy communications maintain a uniform and professional appearance‚ facilitating efficient information dissemination․

Block Format vs․ Modified Block Format

Navy correspondence primarily utilizes the block format‚ where all elements—date‚ address‚ body paragraphs‚ and signature block—align to the left margin․ This creates a clean‚ modern appearance․ The modified block format allows for the sender’s address and date to be right-aligned or centered‚ offering slight stylistic variation․

However‚ the block format is generally preferred for its simplicity and efficiency․ Both formats require single-spacing within paragraphs and double spacing between them․ Choosing the appropriate format depends on specific document requirements and organizational preferences‚ but consistency is key․

Specific Correspondence Elements

Effective correspondence demands attention to detail‚ encompassing precise subject lines‚ professional addressing‚ and appropriate closing remarks with authorized signatures․

Subject Lines: Best Practices

Crafting effective subject lines is paramount for efficient Navy correspondence․ They should be concise‚ accurately reflecting the document’s content‚ and facilitate quick identification and routing․ Avoid vague terms like “Information” or “Regarding․” Instead‚ utilize specific keywords and action phrases․

Prioritize clarity; a well-written subject line minimizes delays and ensures the message reaches the intended recipient promptly․ Consider including relevant codes or identifiers when applicable․ Subject lines should be informative enough to allow readers to prioritize messages effectively‚ contributing to streamlined workflow and improved communication throughout the Department of the Navy․

Addressing and Salutations

Proper addressing and salutations demonstrate respect and professionalism in Navy correspondence․ When addressing individuals‚ use their full name and title unless a closer relationship permits otherwise․ Salutations should align with the formality of the communication; “Dear Mr․/Ms․/Dr․ [Last Name]” is generally appropriate for initial contact․

For official correspondence to flag officers‚ utilize the prescribed format․ Avoid overly casual greetings․ Maintaining a consistent and respectful tone in addressing recipients reflects positively on the Department of the Navy and fosters effective communication․ Accuracy in names and titles is crucial to avoid offense or misdirection․

Closing Remarks and Signatures

Closing remarks should reinforce the purpose of the correspondence and express gratitude where appropriate․ Standard closings include “Sincerely‚” “Respectfully‚” or “Very respectfully‚” depending on the recipient’s rank and the document’s formality․

Signatures are essential for accountability and authentication․ Manual signatures are preferred‚ utilizing blue or black ink․ Electronic signatures are permissible when authorized․ Include the sender’s full name‚ rank (if applicable)‚ and official title below the signature․ Proper closing and signature protocols ensure clarity and demonstrate professionalism within the Department of the Navy’s communication standards․

Handling and Routing of Correspondence

Mail codes and distribution lists facilitate efficient correspondence delivery․ Tracking systems monitor document flow‚ while strict security considerations protect sensitive information․

Mail Codes and Distribution Lists

Mail codes are crucial for accurately directing correspondence within the Department of the Navy’s complex organizational structure․ These alphanumeric designations pinpoint specific offices‚ departments‚ or individuals‚ ensuring documents reach their intended recipients promptly․ Maintaining current and accurate mail code information is paramount for efficient communication flow․

Distribution lists streamline the dissemination of information to multiple individuals simultaneously․ Properly constructed lists minimize redundant distribution and guarantee all necessary personnel receive critical updates․ Regular review and updates of distribution lists are essential to reflect personnel changes and maintain relevance․ Utilizing both mail codes and distribution lists effectively minimizes delays and enhances overall correspondence management․

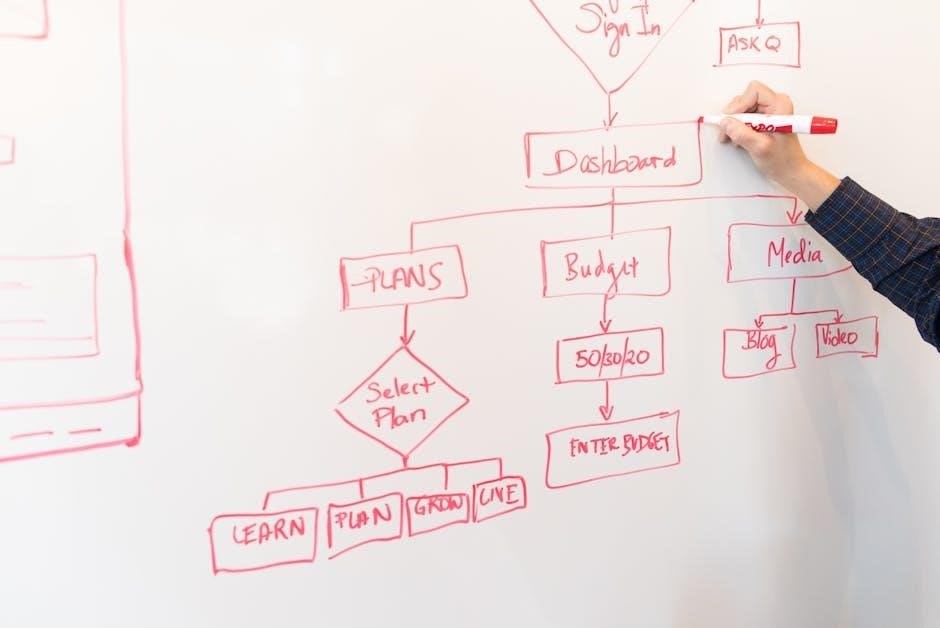

Tracking and Control Systems

Effective tracking and control systems are vital for managing the lifecycle of Navy correspondence‚ from initial creation to final disposition․ These systems ensure accountability and facilitate timely responses to inquiries and requests․ Utilizing established procedures for logging‚ routing‚ and monitoring correspondence is essential for maintaining operational efficiency․

Modern systems often incorporate electronic tracking capabilities‚ allowing for real-time visibility into document status and location․ Regular audits of tracking logs help identify bottlenecks and areas for improvement․ Proper implementation of these systems supports informed decision-making and ensures compliance with Department of the Navy regulations regarding correspondence management․

Security Considerations for Correspondence

Maintaining confidentiality and protecting sensitive information are paramount when handling Navy correspondence․ All personnel must adhere to established security protocols‚ classifying documents appropriately based on their content․ This includes safeguarding against unauthorized access‚ disclosure‚ or modification of information․

Proper handling of classified material requires strict adherence to regulations regarding marking‚ transmission‚ and storage․ Electronic correspondence must be secured using approved encryption methods․ Regular security awareness training is crucial to ensure all personnel understand their responsibilities in protecting sensitive Navy communications and preventing potential breaches․

Specialized Correspondence

Specific document types‚ like Requests for Information (RFIs)‚ reports‚ and Commanding Officer endorsements‚ require unique formatting and content adhering to Navy standards․

Requests for Information (RFIs)

Requests for Information (RFIs) are formal inquiries seeking specific data or clarification․ They must be concise‚ clearly stating the required information and the deadline for response․

RFIs differ from general inquiries; they demand a structured answer‚ often with supporting documentation․ Proper RFI construction includes a detailed subject line‚ a precise question‚ and a designated point of contact․

Ensure RFIs adhere to security classifications and routing procedures․ Avoid ambiguous language and focus on factual requests․ A well-crafted RFI expedites information gathering‚ supporting informed decision-making within the Department of the Navy․

Reports and Submissions

Reports and submissions require meticulous preparation and adherence to prescribed formats․ These documents often detail operational status‚ project progress‚ or investigative findings․ Accuracy and completeness are paramount‚ ensuring data integrity and informed decision-making․

Follow specific reporting templates and guidelines outlined in relevant directives․ Include all required supporting documentation and maintain consistent formatting․ Submissions must be reviewed for clarity‚ conciseness‚ and grammatical correctness before distribution․

Proper routing and timely submission are crucial․ Reports should clearly state the reporting period and any significant deviations from established norms․

Commanding Officer Endorsements

Commanding Officer Endorsements signify approval and accountability for outgoing correspondence․ These endorsements confirm the content’s accuracy‚ compliance with regulations‚ and alignment with command objectives․ They demonstrate the CO’s awareness and support of the information being disseminated․

Endorsements should be concise‚ yet clearly state the CO’s position․ They often include a brief assessment of the document’s impact and any specific instructions for action․ Proper formatting and signature blocks are essential for validity․

Ensure endorsements are reviewed for clarity and professionalism before submission‚ reflecting the command’s commitment to effective communication․

Amendments and Updates to the Manual

Revision Process and Control ensures the manual remains current․ Updates are distributed via online resources‚ maintaining accuracy and reflecting evolving Department of the Navy policies․

Revision Process and Control

The Department of the Navy Correspondence Manual undergoes a rigorous revision process to ensure its continued relevance and accuracy․ Proposed changes are coordinated with the Secretary of the Navy (SECNAV) and relevant stakeholders․ This collaborative approach guarantees that updates reflect current policies and best practices․

A formal control system tracks all revisions‚ documenting the rationale for changes and maintaining version history․ This meticulous record-keeping ensures accountability and facilitates the seamless implementation of updates throughout the Navy․ The process prioritizes clarity and consistency‚ minimizing ambiguity and promoting effective communication across all levels of the organization․ Regular reviews are conducted to identify areas for improvement and address emerging communication challenges․

Distribution of Updated Manuals

Following the revision and approval process‚ updated versions of the Department of the Navy Correspondence Manual are distributed widely throughout the Navy․ SECNAV oversees the dissemination‚ ensuring all personnel have access to the most current guidance․ Distribution methods include electronic publication on official Navy websites and through established communication channels․

Commands are responsible for notifying their personnel of updates and ensuring the manual is readily available․ This proactive approach promotes consistent application of correspondence standards․ Furthermore‚ training materials are often updated concurrently to reinforce the new guidelines․ Accessibility is a key priority‚ with efforts made to provide the manual in various formats to accommodate diverse needs․

Online Access and Resources

The Department of the Navy Correspondence Manual is readily accessible online through official Navy portals and websites․ These digital resources provide convenient‚ 24/7 access for all personnel․ SECNAV supports maintaining a current and user-friendly online presence for the manual․ Supplementary materials‚ such as FAQs‚ templates‚ and training modules‚ are also available․

Personnel can utilize these online resources to quickly find answers to correspondence-related questions and ensure compliance with established standards․ Regularly updated content guarantees the information remains accurate and relevant․ Furthermore‚ links to related policies and guidance are provided for comprehensive understanding and efficient workflow․