Samsung reimagines laundry with innovative technology, offering a superior cleaning experience; this VRT Steam Washer user manual guides you through its advanced features.

This appliance, like the WF520, combines powerful performance with gentle fabric care, utilizing VRT Plus technology for minimized vibrations and quiet operation.

Explore how to maximize efficiency and enjoy consistently fresh, clean laundry with this comprehensive guide, designed for both new and experienced Samsung appliance users.

Overview of VRT Technology

Samsung’s VRT (Vibration Reduction Technology) is a core innovation designed to enhance the laundry experience by dramatically minimizing vibrations and noise during operation. This technology employs a unique four-point support system coupled with a balanced drum, effectively distributing weight and reducing unwanted movement.

The advanced VRT Plus system, found in models like the WF520, takes this a step further, offering even greater stability and quieter performance, even during high-speed spin cycles. This is particularly beneficial for homes with multiple floors or open-concept living spaces.

By reducing vibrations, VRT not only minimizes noise disruption but also protects the washer itself, contributing to its longevity and reliability. It allows for larger capacity drums without compromising stability, delivering powerful cleaning performance with exceptional quietness.

Key Features and Benefits

The Samsung VRT Steam Washer boasts a suite of features designed for optimal cleaning and convenience. Steam Wash technology gently yet powerfully removes stains and allergens, sanitizing clothes without harsh chemicals. Its large capacity drum accommodates bulky items like comforters, saving time and energy.

VRT Plus technology ensures quiet operation, while SmartThings App integration allows remote control and monitoring. Specialized wash cycles cater to diverse fabric types, including delicate items and heavily soiled loads.

Benefits include improved cleaning performance, reduced noise levels, enhanced fabric care, and increased convenience. The Self-Clean+ cycle maintains washer hygiene, while the durable construction ensures long-lasting reliability, making it a valuable addition to any home.

Installation Guide

Proper installation ensures optimal performance and longevity of your Samsung VRT Steam Washer; carefully follow these steps for water, electrical connections, and inspection.

Unpacking and Inspection

Carefully unpack your new Samsung VRT Steam Washer, ensuring you have ample space to maneuver and avoid damaging the appliance or your flooring. Begin by removing all packaging materials, including cardboard, plastic wrap, and foam inserts.

Thoroughly inspect the washer for any visible signs of damage incurred during shipping. Look for dents, scratches, or broken parts on the exterior. Check the door seal for integrity and ensure it’s properly attached.

Verify that all included accessories are present, such as the water inlet hoses, drain hose, and any documentation like the user manual and warranty information. If any damage is detected or accessories are missing, immediately contact your retailer or Samsung customer support. Do not attempt to operate a damaged appliance.

Retain the original packaging materials for potential returns or warranty claims. Proper documentation of any initial damage is crucial for a smooth resolution process.

Connecting Water Supply

Before connecting the water supply, ensure the water shut-off valves are completely closed. Identify the hot and cold water inlets on the back of the washer; they are typically color-coded. Attach the provided water inlet hoses to the corresponding inlets, tightening securely by hand, then using pliers for an additional half-turn.

Connect the other ends of the hoses to the appropriate hot and cold water faucets. Ensure the connections are snug to prevent leaks. Slowly open the water shut-off valves, checking for any leaks at both the washer connections and the faucet connections.

If leaks are detected, immediately close the valves and re-tighten the connections. Do not operate the washer until all leaks are resolved. Consider using Teflon tape on the threads for a more secure seal.

Electrical Connection Requirements

This Samsung VRT Steam Washer requires a dedicated 120V, 60Hz electrical outlet. Do not use extension cords or adapters, as they can pose a safety hazard. The washer must be properly grounded to prevent electric shock. Verify your outlet meets these specifications before installation.

The electrical outlet should be located within reach of the power cord, and protected from moisture. Never attempt to repair the power cord yourself; if damaged, it must be replaced by a qualified technician. Ensure the circuit breaker for the outlet is appropriately sized – typically 15 or 20 amps.

Improper electrical connection can void the warranty and create a dangerous situation. Always consult a qualified electrician if you are unsure about your electrical system’s compatibility.

Operating Instructions

Unlock the full potential of your Samsung VRT Steam Washer by understanding its intuitive controls and diverse wash cycles for optimal cleaning performance.

Control Panel Explained

The Samsung VRT Steam Washer’s control panel is designed for intuitive operation, featuring a digital display and clearly labeled buttons. The Power button initiates or deactivates the washer, while the Start/Pause button controls the wash cycle. Use the Cycle Selector dial to choose from various pre-programmed cycles like Normal, Delicate, Heavy Duty, and Quick Wash.

Steam options are conveniently located for sanitizing and wrinkle reduction. Temperature settings allow adjustments for water heat, catering to different fabric types. Spin Speed controls the intensity of the final spin, impacting moisture levels. Additional options include Delay Start for scheduling washes and Self Clean+ for maintaining washer hygiene. The display provides cycle progress, estimated time remaining, and error notifications, ensuring a seamless laundry experience.

Selecting Wash Cycles

The Samsung VRT Steam Washer offers a diverse range of wash cycles to accommodate various fabrics and soil levels. For everyday items, the Normal cycle provides a balanced wash. Delicate is ideal for lingerie and fragile materials, utilizing a gentle wash action. Heavy Duty tackles heavily soiled items like work clothes and towels, employing a more vigorous cleaning process.

The Quick Wash cycle efficiently cleans lightly soiled loads in a shorter timeframe. Specialized cycles include Sanitize, utilizing steam to eliminate bacteria, and Permanent Press, minimizing wrinkles. Consider the Bulky Items cycle for comforters and bedding. Always refer to garment care labels to select the most appropriate cycle, ensuring optimal cleaning and fabric protection.

Using Steam Functions

The Samsung VRT Steam Washer incorporates steam technology to enhance cleaning performance and fabric care. The Steam Wash cycle penetrates fabrics deeply, loosening dirt and stains for a more thorough clean. Steam Sanitize eliminates 99.9% of bacteria and allergens, ideal for sensitive skin or baby clothes. Utilizing steam reduces the need for harsh detergents, protecting fabric integrity.

The Steam Refresh cycle quickly removes wrinkles and odors, revitalizing clothes without a full wash. To activate steam functions, select the desired cycle and then press the Steam button on the control panel. Ensure the steam reservoir is filled for optimal performance. Steam cycles may extend wash times slightly, but deliver superior results.

Detergent and Additives

Samsung recommends using HE (High Efficiency) detergents for optimal performance and to maintain washer integrity; always follow detergent manufacturer guidelines carefully.

Recommended Detergent Types

For your Samsung VRT Steam Washer, utilizing High Efficiency (HE) detergents is crucial for optimal cleaning performance and to prevent issues like excessive suds or residue buildup. Traditional detergents create too many suds, interfering with the washer’s sensors and reducing cleaning effectiveness.

Liquid HE detergents are generally preferred, dissolving completely and distributing evenly throughout the wash load. Powdered HE detergents are also acceptable, but ensure they dissolve fully, especially in cold water washes. Pods or packs are convenient, but always place them directly into the drum, not the dispenser, to avoid clogging.

Consider detergents specifically formulated for steam washers, as they are designed to work effectively with the steam cycles, enhancing stain removal and sanitization. Avoid using detergents containing fabric softeners or bleach alternatives, as these can interact negatively with the steam functions or damage the washer’s components. Always refer to the detergent packaging for specific usage instructions and compatibility with HE washers.

Detergent Dispenser Usage

Your Samsung VRT Steam Washer features a multi-compartment dispenser drawer, typically located on the upper left side of the machine. This drawer is specifically designed for liquid or powdered HE detergent, fabric softener, and bleach; Always check your washer’s model for specific compartment markings.

For detergent, fill the designated compartment to the maximum fill line, adjusting the amount based on load size and soil level. Do not overfill, as this can cause detergent to dispense prematurely. For fabric softener, dilute liquid softener with water according to the softener’s instructions before pouring it into the appropriate compartment;

Bleach should be diluted with water and poured into its designated compartment. Avoid direct contact with clothes. Regularly clean the dispenser drawer to prevent buildup and ensure proper function. Remove the drawer and rinse thoroughly with warm water, removing any lingering detergent or softener residue.

Using Fabric Softener and Bleach

Fabric softener adds a pleasant scent and reduces static cling; dilute liquid softener with water before adding it to the designated dispenser compartment – never pour directly onto clothes. Bleach, used sparingly, brightens whites and disinfects; always dilute bleach with water and use the appropriate compartment to avoid discoloration.

Important considerations: avoid using bleach on colored fabrics. Regularly inspect the dispenser for residue buildup, cleaning it with warm water to ensure proper dispensing. Overuse of fabric softener can reduce towel absorbency. Always follow the garment care label instructions regarding bleach and softener use;

Samsung VRT Steam Washers are designed to efficiently utilize these additives, but proper dilution and compartment usage are crucial for optimal results and to prevent damage to your machine or clothing.

Maintenance and Cleaning

Regular cleaning preserves performance and longevity; maintain your Samsung VRT Steam Washer with routine drum, dispenser, and filter cleaning procedures for optimal results.

Cleaning the Washer Drum

Maintaining a clean washer drum is crucial for preventing odors and ensuring optimal cleaning performance. Samsung recommends utilizing the Self-Clean+ cycle regularly – approximately once a month, or more frequently with heavy use. This cycle employs steam and powerful water jets to eliminate detergent residue, fabric softener buildup, and mildew.

Before initiating the Self-Clean+ cycle, ensure the drum is empty. You may add a Samsung Washer Cleaner, or a cup of white vinegar, directly into the detergent dispenser for enhanced cleaning. Avoid using harsh chemicals or abrasive cleaners, as these can damage the drum’s surface. For a manual clean, wipe down the drum with a damp cloth and mild detergent after each wash, paying attention to the door seal.

Leaving the washer door slightly ajar after each use promotes ventilation and prevents moisture buildup, further contributing to a fresh and hygienic drum environment.

Cleaning the Detergent Dispenser

Regularly cleaning the detergent dispenser prevents clogs and ensures accurate detergent distribution, maintaining optimal wash performance. Samsung recommends cleaning the dispenser drawer at least every two months, or more frequently if you notice residue buildup. To remove the drawer, locate the release button or lever – typically found inside the dispenser compartment – and gently pull it out.

Rinse the dispenser drawer and its individual compartments under warm running water, using a soft brush to remove any lingering detergent or fabric softener residue. For stubborn buildup, soak the drawer in warm water with a mild detergent for approximately 30 minutes before rinsing. Ensure all compartments are thoroughly cleaned and dried before reinserting the drawer.

Inspect the dispenser housing within the washer for any remaining residue and wipe clean with a damp cloth.

Filter Cleaning Procedures

Maintaining a clean filter is crucial for optimal washer performance and prevents drainage issues. Samsung advises cleaning the drain filter every three months, or immediately if an error code indicates a blockage. Locate the filter access panel, usually at the front bottom of the washer. Have a towel and shallow container ready to catch any residual water.

Gently unscrew the filter cap, turning it counterclockwise. Be prepared for water to drain out. Remove any lint, debris, or foreign objects from the filter. Rinse the filter thoroughly under running water, ensuring all obstructions are removed. Inspect the filter housing for any remaining debris and clean as needed.

Reinstall the filter cap, tightening it securely.

Troubleshooting Common Issues

Addressing common problems ensures continued optimal performance; this section details solutions for issues like the washer not starting, or failing to fill/drain properly.

Washer Not Starting

If your Samsung VRT Steam Washer fails to start, begin by verifying the power cord is securely plugged into a functioning electrical outlet. Check the circuit breaker or fuse box to ensure the circuit hasn’t tripped or blown; reset if necessary.

Confirm the door is completely closed and latched; the washer won’t operate if the door isn’t properly secured. Also, examine the control panel for any illuminated error codes, as these provide valuable diagnostic information.

Ensure the start/pause button has been firmly pressed. If the issue persists, try disconnecting the washer from the power supply for a few minutes, then reconnecting it to reset the internal systems. A faulty lid switch or motor could also be the cause, potentially requiring professional service.

Water Not Filling or Draining

If your Samsung VRT Steam Washer isn’t filling with water, first check that both hot and cold water supply valves are fully open. Inspect the inlet hoses for kinks or obstructions that could restrict water flow. A clogged water inlet filter can also prevent proper filling; locate and clean this filter carefully.

For draining issues, verify the drain hose isn’t kinked, clogged, or positioned too high. Ensure the drain hose is securely inserted into a standpipe or laundry tub. Check the drain pump filter for lint, debris, or small objects that may be causing a blockage; clean it thoroughly.

If problems continue, a faulty water inlet valve or drain pump may require professional attention.

Error Codes and Their Meanings

Samsung VRT Steam Washers utilize error codes to diagnose issues. A code like “4E” or “4E” typically indicates a water supply problem – check inlet hoses and valves. “5E” or “5C” signals a draining issue; inspect the drain hose and pump filter for obstructions.

“UE” often points to an unbalanced load, requiring redistribution of clothes within the drum. “HE” suggests the water isn’t heating correctly, potentially due to a faulty heater element. “LE” indicates a water leak detected by the washer’s sensors.

Consult your full user manual for a comprehensive list and specific troubleshooting steps for each error code. Ignoring error codes can lead to further damage.

Advanced Features

Samsung’s SmartThings integration, Self-Clean+ cycle, and enhanced VRT Plus noise reduction elevate laundry experiences, offering convenience and powerful performance.

SmartThings App Integration

Unlock seamless control and monitoring of your Samsung VRT Steam Washer with the SmartThings app, available for both iOS and Android devices. This integration allows for remote operation, enabling you to start or pause cycles from anywhere with a Wi-Fi connection.

Receive real-time notifications regarding cycle completion, and potential maintenance needs, ensuring your washer operates optimally. The app also provides customized wash cycle recommendations based on your laundry habits and fabric types.

Utilize the Smart Diagnosis feature for quick troubleshooting; the app can detect and diagnose minor issues, offering solutions without requiring a service call. Monitor energy consumption and track water usage to promote eco-friendly laundry practices. Enjoy a connected laundry experience with SmartThings!

Self-Clean+ Cycle

Maintain optimal hygiene and performance with the Self-Clean+ cycle, a powerful feature designed to deep clean the washer drum without harsh chemicals. This cycle utilizes steam and water jets to remove detergent residue, fabric softener buildup, and potential mold or mildew growth.

The Self-Clean+ cycle is recommended to be run approximately once a month, or more frequently depending on usage, to ensure a consistently fresh and clean washing environment. It’s a convenient and effective way to prolong the life of your Samsung VRT Steam Washer.

Simply activate the cycle from the control panel, and the washer will automatically handle the cleaning process. This feature contributes to better laundry results and a healthier home environment, eliminating unwanted odors and allergens.

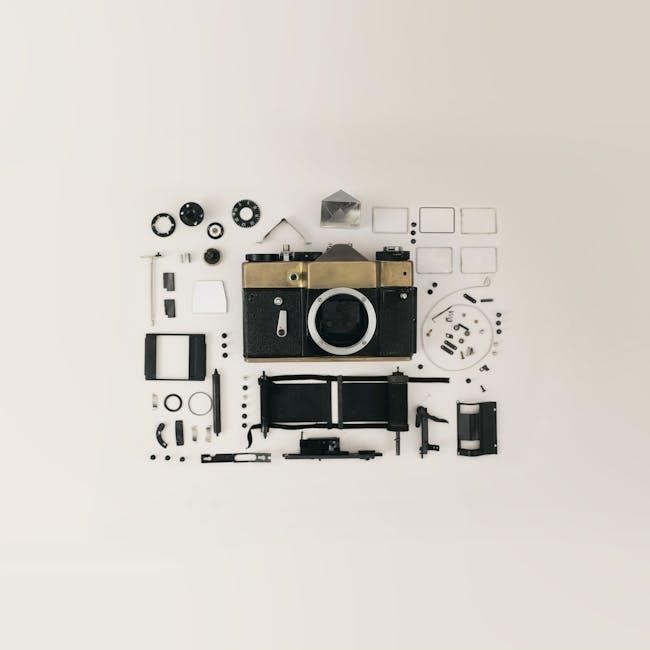

VRT Plus Noise Reduction System Details

Samsung’s VRT Plus technology significantly minimizes vibrations and noise during operation, creating a quieter laundry experience. This advanced system employs a unique four-point support structure and a balanced drum design to effectively dampen vibrations, even at high spin speeds.

Unlike conventional washers, the VRT Plus system dynamically adjusts the balance of the load, reducing noise levels and preventing the washer from “walking” during operation. This is particularly beneficial for homes with multiple floors or sensitive family members.

The enhanced dampening materials and optimized suspension further contribute to the quiet performance, making your Samsung VRT Steam Washer a welcome addition to any home, offering powerful cleaning with minimal disruption.